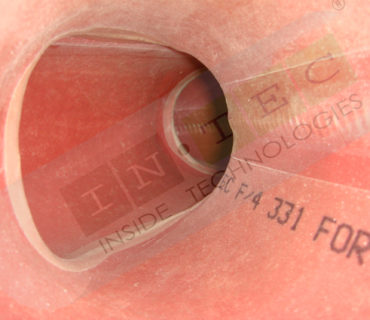

The most advanced, environment-friendly and rapid solution to solve the problem of leaking pipes installed in civil and industrial buildings with diamenters from 40mm to 300mm.

In almost 30 years of activity, IN•TEC, thanks to a dedicated team, has always been at the forefront of innovation in the No-Dig rehabilitation of vertical and horizontal drain pluvial and sewer pipes.

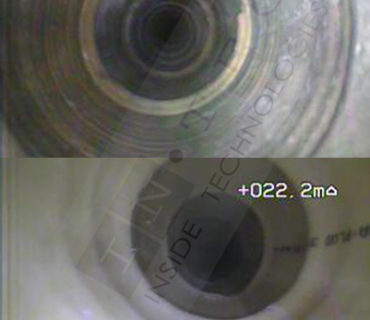

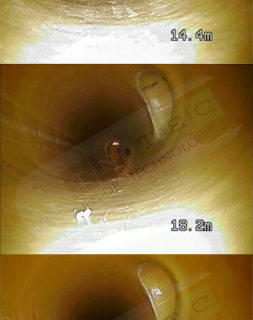

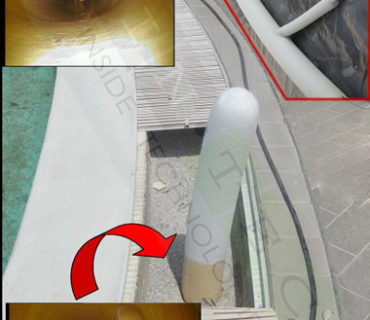

The methods of application are different, complementary and interchangeable in relation to the type of piping, the ruptures detected and the operational peculiarities. The technical staff will suggest the most suitable technique based on what is found during the video inspection phase and the rehabilitation modalities can be:

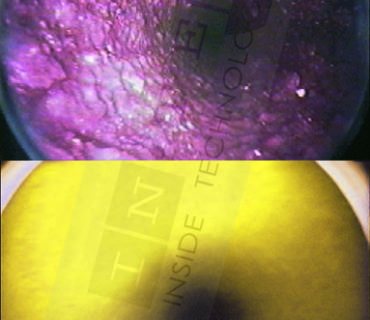

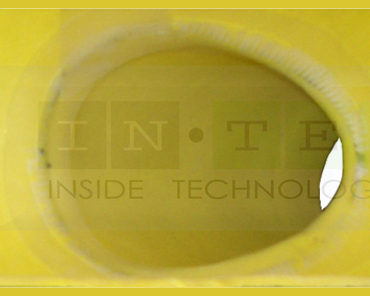

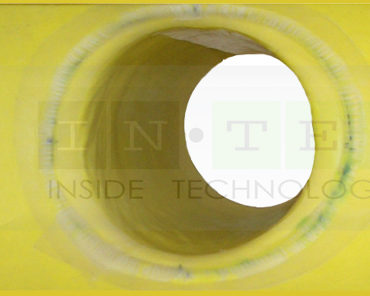

- rehabilitation with flexible liners made of PU coated polyester fabric, impregnated with epoxy resin; structural and thixotropic

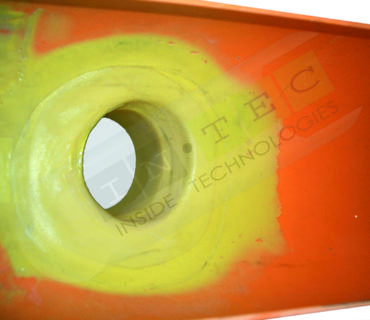

- rehabilitation using structural and tixotropic epoxy resin spraying techniques (a feature that prevents dripping),

- hybrid rehabilitation with column portions treated with flexible liners/epoxy resin and others with epoxy spray.